Specifications

Rock-solid specification testing during the manufacturing process is at the heart of business success and public safety. At different locations in your factory, and at different stages of the manufacturing process, you perform measurements to uphold quality standards. Be they samples, calibrations, checking the quality of an end product or byproduct, certain requirements (internal agreements, customer arrangements, legal obligations) have to be met. To verify whether measurements meet these requirements, you convert them into (hard) limits or specifications.

Automation ensures quality and saves you the trouble of testing every product after production. Filling your specifications in AlisQI, you’ll enjoy a smart system that tests all measurements and notifies you of any inconsistencies. You can add specifications and tailored notes (to add additional context) for each analysis set and every product.

This article shows you how to set up and use specification limits in AlisQI as well as implementing Notes to your sets/results.

Specification limits are different from control limits. Specification limits are values set by the end-user to define an acceptable process or product quality. Control limits, in contrast, appear on control charts and set the upper and lower range of acceptable variation during a process.

This feature is available with an active subscription to either one of these solvers:

In this article

Introduction

This video shows how AlisQI deploys specifications in its quality control.

Specification versions

A specification version is a set of specifications with a start date. AlisQI continuously compares result values to the specification version that is valid at the time of measurement.

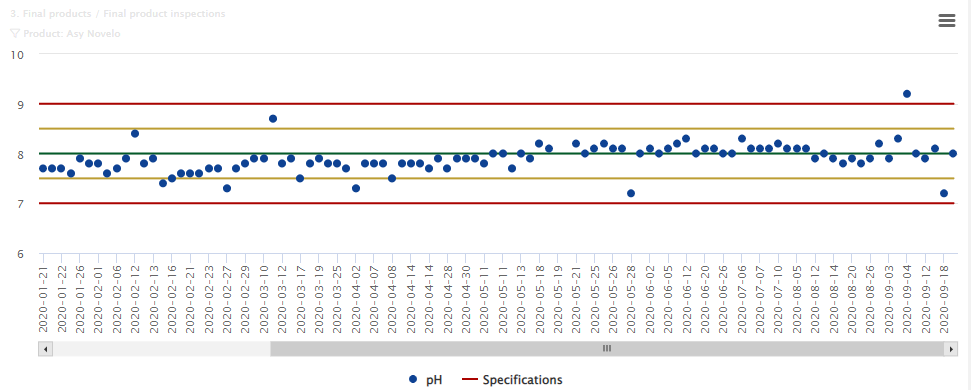

The control chart below shows measurement values and their specification version.

If there were a second spec version, we would see a shift in the specification lines.

Specification limits

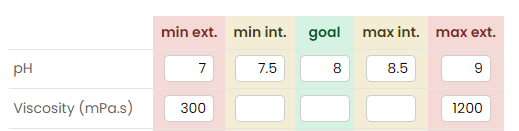

An AlisQI specification version has five fields of numeric values:

- one target (goal)

- two internal limits

- two external limits

The two external limits (red) are used to indicate absolute limits. If these limits are breached the result value is off-spec. In case of an off-spec, an alarm is generated automatically. The two internal limits (orange) indicate that the absolute limits are in danger of being breached. The purpose of these limits is to warn the user that measurement is drifting outside a safe range.

When setting external or internal limits, it is not necessary to distribute values symmetrically, nor is it not necessary to fill in all limit fields. This flexibility gives users the ability to customize specification versions.

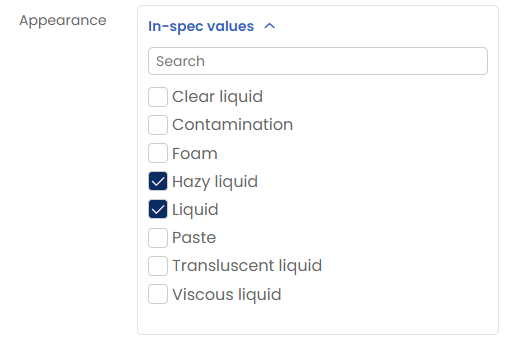

With selection lists it is possible to select which options are in-spec. The rest is automatically off-spec.

For selection lists, there is no distinction between internal and external specifications.

Index fields and options

For analysis sets with an index field, you can specify different specification versions for each index option. This makes it possible, for example, to use different specification versions for each end product, customer, or sample type.

Together with the field visibility, this function is the rationale of index fields.

Generic specifications

Of course, it is also possible to apply a single specification version to all options. Check the box on the Specification management screen (as shown in the screenshot below).

You can create exactly one specification version per index field option (e.g. product). In our model, a product is uniquely defined by its specifications. Therefore, it is not possible to create multiple specifications for a single product.

If a generic specification version (for all options) and a specific specification version (for one option) exist for the same period, AlisQI applies the latest version. In this way, you can define an exception to the generic specifications.

For example, there is a generic specification version with a January 10 start date and a specific specification version for product Asy Novelo with a January 20 start date.

In this example:

- no specification applies before January 10

- between 10 and 20 January, the generic applies to all products

- from January 20 onwards, the generic applies to all products except for Asy Novelo

Each specification version has a start date. You cannot change this start date. Luckily, there is a workaround!

Creating a new specification version

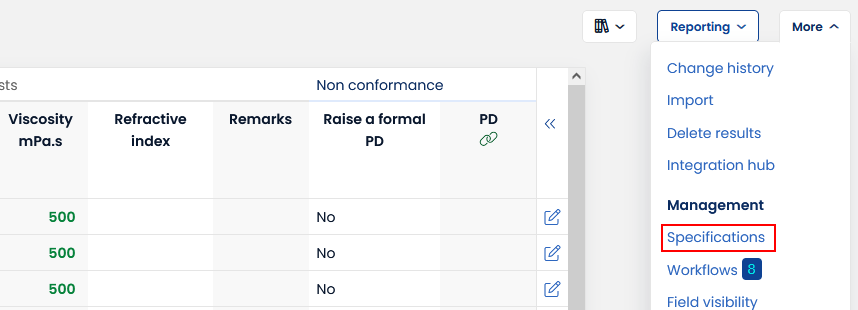

You can create a new specification version for an analysis set by navigating to Toolbar » More » Specifications in the results overview for that specific analysis set.

Import and export

Specifications can be imported and exported by means of Excel files. Navigate to Toolbar » More » Specifications from the Results overview. There you will see export and import buttons.Import

To import specifications you start by downloading an import template (Excel). Populate that template in Excel and then upload it to AlisQI to import your active specifications.

Each file upload must be 16 MB or smaller, with a total limit of 50 MB.

Export

Specifications can be exported in Excel format by clicking Toolbar » More » Download Excel.

Applications

Once you set specifications, they can be used in several ways:

- Alarms

AlisQI generates alarms for off-specs. For more information, see the alarms article in our knowledge base. - Specification testing

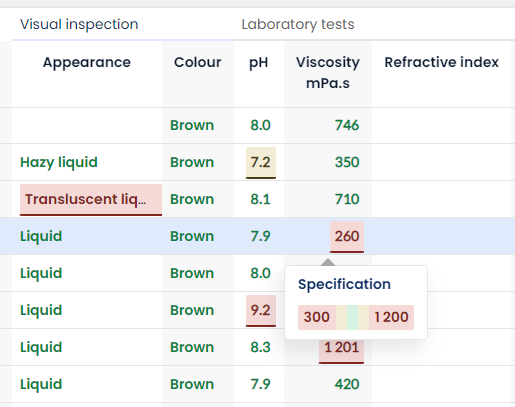

Specification testing takes place when inputting data, as well as in the results overview. Color coding indicates the specification range of the measured value.

-

Statistics

The statistics overview shows the number of counted results for each specification range. From here, you can click through directly to the underlying results.

Specification evaluation

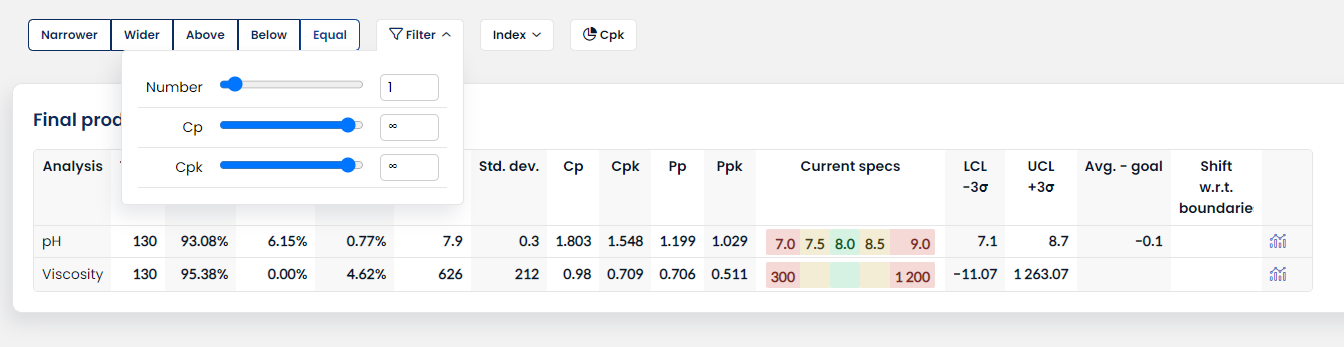

Every once in a while you might want to evaluate all your production to see how capable your operation is in producing those products. This is what the specification evaluation functionality is for. It evaluates all your products and provides detailed statistics on your actual performance and the offset with the target specifications. This will help you to identify quality risks and bottlenecks.

From the results overview, go to:

Toolbar » Reporting » Specification evaluation

Or if you want to evaluate data for multiple sets, go to:

Menu » Reporting » Specification evaluation

For every product in this analysis set, you will see a table like the one above. This table includes a set of descriptive statistics, including capability indicators.

In order to focus on the bottlenecks and filter out the well-performing products, use the Cp/Cpk filter:

Classification

The classification (Shift) indicates how the specs compare to the measured process variation. The outcome can either be narrower, wider, above, below or equal.

Click the histogram icon for a graphic representation of this classification.

Changing the start date of a spec version

Each specification version has a start date. You cannot change this start date. Luckily, there is a workaround!

If you have a specification version that you want to change the start date for, ctrl-click on the copy icon to open it in a new tab of your browser. Then delete the specification version in your first tab, switch to the newly opened tab, adjust the date and save.

Now you basically created a new spec version with the same specifications, but with a different start date.

Notes

The Notes functionality can help your organization provide additional context to fields in a form and can increase the accuracy and quality of data input.

They can be applied to an entire analysis set or to specific index field values. Notes can include general instructional information or more detailled guidance relating to expected values/outcomes.

To add notes:

1. Go to the Specifications overview page.

2. Click the “Notes” button at the top of the page or the note icon next to a specification.

3. On this Notes page, you can add instructions and details. Choose whether your note applies to the whole analysis set or just a specific index field. Input the applicable information and SAVE.

Once saved, notes will appear in the Specifications panel when completing a result form.

You can configure the panel to automatically open in Application Settings:

Please be aware that Notes are not versioned.

Links

To further enhance the flexibility of the Notes function, custom URL links can be added to a notes section.

These links can bring you anywhere, both within AlisQI or to external destinations. Links should be defined via Markdown notation, where you provide a link text and URL, as shown below:

1 Notation:

2 [link text](url)

3

4 Example:

5 [AlisQI website](https://www.alisqi.com)