SPC Out-of-control detection

Managing a plant with statistical process control (SPC) charts is a bit like driving on the highway. Both actions involve high-speed data processing and require an eye for detail. Positive outcomes often correlate with the operator's ability to stay between the lines. On the highway, it's the two painted lines. In the plant, control chart lines define upper and lower limits of natural variation. When data points cross a line, the process is out of statistical control, a sign that potential danger might be fast approaching. To capture that information in real time and act on those insights, you need a robust SPC system.

This article shows you how to monitor process data and create alerts when the SPC system detects out-of-control patterns.

AlisQI applies Nelson Rules to detect variation and find matching patterns in data sets. When AlisQI detects a pattern with any of Nelson's eight rules, the process is likely out of control, and you can expect deviations.

See the Wikipedia article for a definition of the eight rules.

In this article

AlisQI SPC functionality: building blocks

You monitor process data by creating a rule tool. That tool has three building blocks.

- Rule set: This is where you quantify the Nelson Rules you'd like to apply for a subset.

- Profile: Tells the system how to evaluate data.

- Alarm: Data analysis becomes actionable here. When an out-of-control pattern is detected, the system generates an alarm based on your Alarm functionality settings. In the SPC profile, the user defines what type of alarm to raise. In the alarm settings, the user assigns certain alarm types to specific users.

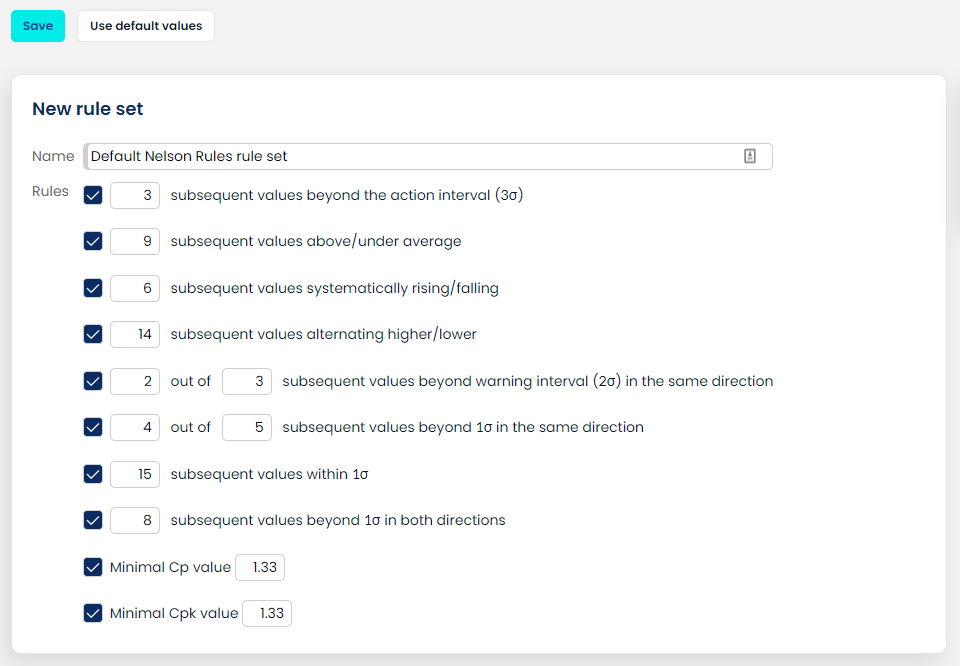

Rule set

With the help of a rule set (see screenshot below), you decide how to apply the Nelson Rules for your subset and if you'd like to apply all of them. The small checkbox on the left of each rule allows you to select all the rules that you want to activate in this profile. This way, you can fully tailor the monitoring to your needs. Next to the Nelson Rules, you can have the system monitor a minimal Cp and Cpk value.

You define a rule set once and use it with any number of analysis sets or profiles (more info on this in the section below).

To define a rule set, click Menu » Reporting » Alarms » Manage SPC rule sets

Rule sets give you a range of customization options. If you want to define different testing levels for a given analysis set, simply create multiple rule sets. For example, some parameters (analysis set fields) may require a more tolerant inspection than others.

Need a reporting scheme that manages escalation? You could configure the system to send alarms about minor issues to operators and alarms about major issues to supervisors.

To get you up and running as quickly as possible, click the “Use default values” button. This will activate all rules and set them to the default as defined in statistical literature. If needed, you can adjust any of these.

Profile

The profile drives AlisQI's SPC functionality. It pulls together rule sets, data analysis, and alarm settings into one easy-to-manage dashboard. You can create multiple profiles for any analysis set.

Use the profile to define:

- the data set you want to evaluate

- data evaluation methods

- where to send reports

To create a profile, go to Results overview and click: Toolbar » More » SPC Profiles

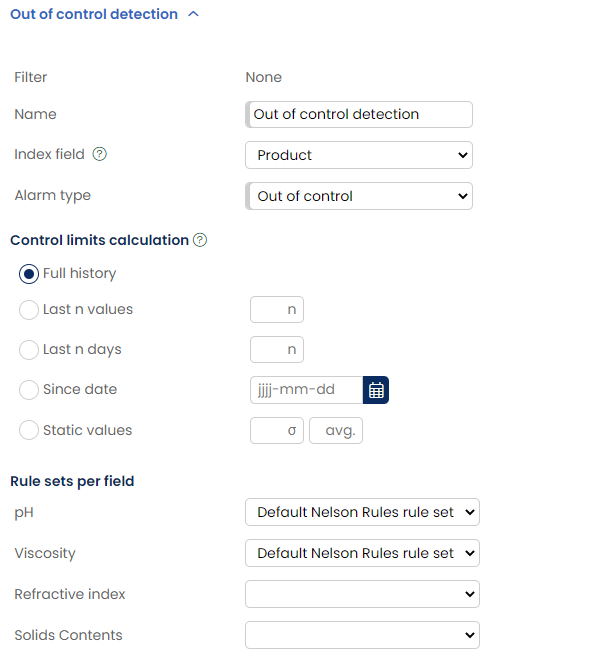

Here, you fill out a short form that tells the system about the data you'd like to evaluate (see image below).

Profile features

A profile has four main settings.

New profile - data set definition

Define the data set you want to evaluate. The next step, which is optional, is to apply a filter. A profile filter excludes data set values that do not match the filter settings. If you apply a filter in the Results overview, AlisQI automatically uses that filter in the profile.

Finally, use the Index field to evaluate results for each option in the selection list element. For example, imagine you have a "Machine" selection list, and you want to evaluate data per machine. Setting the Index field setting to "Machine" means the evaluation only includes results that share the Machine value. Your profile Index field can differ from the Index field of the analysis set (which can for instance refer to products, enabling you to add specs per product).

Alarm type

Use the Alarm type field to define which alarm to use when the SPC system observes an out-of-control pattern. You can select the default alarm to generate a report or create a custom alarm. More information about managing alarms is here.

A combination of the profile and custom alarms give users the flexibility to notify the right people. Out-of-control processes might still deliver within specification products. So there is no immediate problem, as the product can still be shipped to the market. There might be no reason to trigger the shop floor in this situation, but process engineers instead.

Control limits calculation

Nelson Rules use control limits to detect variation in the data. We use these rules to calculate upper and lower control limits of natural variation with averages and standard deviations.

By default, AlisQI uses all values (the Full history option) in the constrained data set to calculate control limits. (The filter and Index field are always applied.) If you'd like to apply a custom solution, select a data set option on the Manage SPC profiles screen:

- Full history: the complete data set

- Last n values: the last n values

- Last n days: values from the previous n days

- Since date: data since a specified date

- Static values: user-defined average and standard deviation

The calculation of control limits requires a minimum number of values. If the number of values is below the defined threshold, no evaluation takes place. The threshold default is 25.

Open the application settings of the reporting section to change the default.

Rule sets per field

You can specify which rule sets apply to each numeric field. Not all fields need an assigned rule set.

Evaluation

Automatic evaluation and notification

AlisQI activates the profile as soon as you click Save on the Manage SPC profiles screen.

Every time the SPC system records a data pattern result, it scans all profiles for a matching data set definition.

When there is a rule set match (i.e. the SPC system detects a pattern in the data set), AlisQI issues an alarm and sends users a notification based on the alarm assignments.

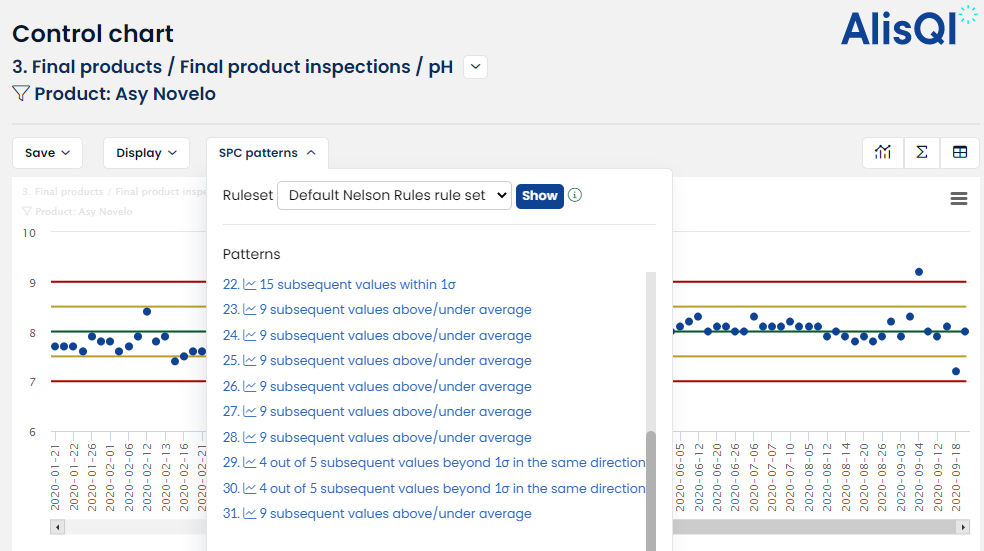

Manual evaluation

You can also run a manual evaluation from a control chart. Manual evaluations are for one-off inspections of the data. They require just a rule set and do not need a profile.

Whenever there is at least one rule set, an SPC Patterns button displays in the Control chart toolbar. Should there be more rule sets, you can select the one you want to apply to the data in the control chart. That's the extent of your manual work. AlisQI takes over and evaluates the data set in the control chart. If any patterns are found, the system creates a list. Click on a pattern to see it light up in the chart.

It's worth noting that the manual evaluation tool calculates control limits with the Full history (under the filter).

Example use cases and configuration

Out-of-control detection is a powerful building block in our platform. It enables you to automate operations, detect drifting processes or get triggers when instruments need to be calibrated. The list of use cases is extensive. We are often surprised by the creativity of our users in creating process automation.

Control charts play a big part in SPC out-of-control detection. Operators use them to monitor and control a process. This onboarding article teaches you how to use them.

We created a shortlist of example use cases and their configurations. It's hardly complete. We aim to show you how AlisQI out-of-control detection can help you make quality management smart and omnipresent.

- Detect sliding processes

When your process is out of control and systematically rising or falling, we can expect off-specs. Having this monitor in place ensures that we will be notified in case of a drifting process. No need for manual monitoring. Just sit back and wait for the system to alert you of any deviations.

Configuration

Configure a rule set including rule #3, representing a sequence of rising or falling measurements. A sequence of length 6 is defined as the default in literature, but in AlisQI, you can adjust everything to your needs. Activate a profile for your data set and you’re done. - Get triggers for instrument calibrations – Shewhart Control Charts

In your quality operation measurement data need to be trustworthy. This means that your instruments need to be calibrated at all times. But calibration takes time and can be costly. So you only want to do that when necessary.

The engine running our process out-of-control detection can be applied to your reference samples as well. If you analyze the same reference sample every day, and strictly follow your standard operating procedure, the only cause of variation left is your instrument. That means that any OOC pattern found in your data should lead to instrument calibration. - Automatic capability studies with alerts on Cp(k) thresholds

We extended the Nelson rules with monitors for the running Cp/Cpk value. Whenever a Cp/Cpk value falls under the threshold value you set, you will be notified. This automates your capability studies. Configure once, sit back and wait for the system to notify you.

Configuration

Create a rule set that activates rules #9 or #10, with a threshold value for Cp and/or Cpk. Activate a profile for your data set and you’re all set.